Scheduled Test

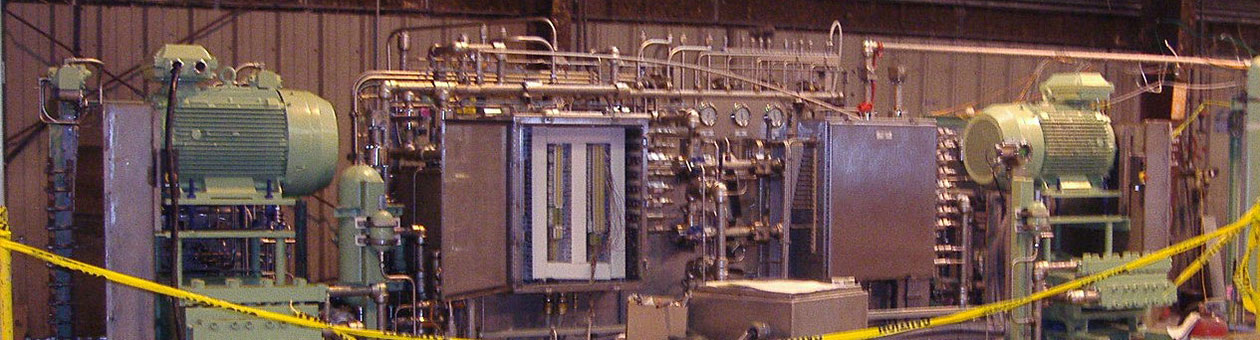

A Factory Acceptance Test (FAT) is a scheduled test, taking place at the fabrication plant in which all purchased equipment will be demonstrated as specified in the purchase order.

Besides witnessing the equipment trials several other benefits are gained.

- The FAT becomes an ideal occasion to review the bill of materials and to discuss spare parts required for start-up and use during the first year of operation.

- A complete documentation review gives confidence in maintenance procedures.

- An installation scope meeting in order to review the critical parameters and tolerances regarding equipment set-up.

Below is the basic list of parameters considered by SVENDBORG WAVE ApS when validating equipment prior to shipment.

Representatives from several disciplines can be required to ensure that the proper eyes are placed in all areas.

Engineering

- Utility requirement lines identified on equipment per general arrangement drawings.

- Start-up requirements for utilities mapped

- Start-up calendar and milestones identified

- Start-up resources and responsibilities committed

- Critical equipment placement procedures and tolerances reviewed

- Coordination of sub-contractor support defined

- Electrical and mechanical tagging of the equipment as per specifications

- Measure critical tolerances of equipment.

Operations

- Equipment operates as specified

- Human Machine Interface is functional

- Operator procedures reviewed as per manuals

- Override system reviewed

- Machine safety parameters tested

- Training schedule review

- Weight load capacity tests of all equipment witnessed.